Investment casting-made impellers: Innovation, efficiency and precision at the service of industry

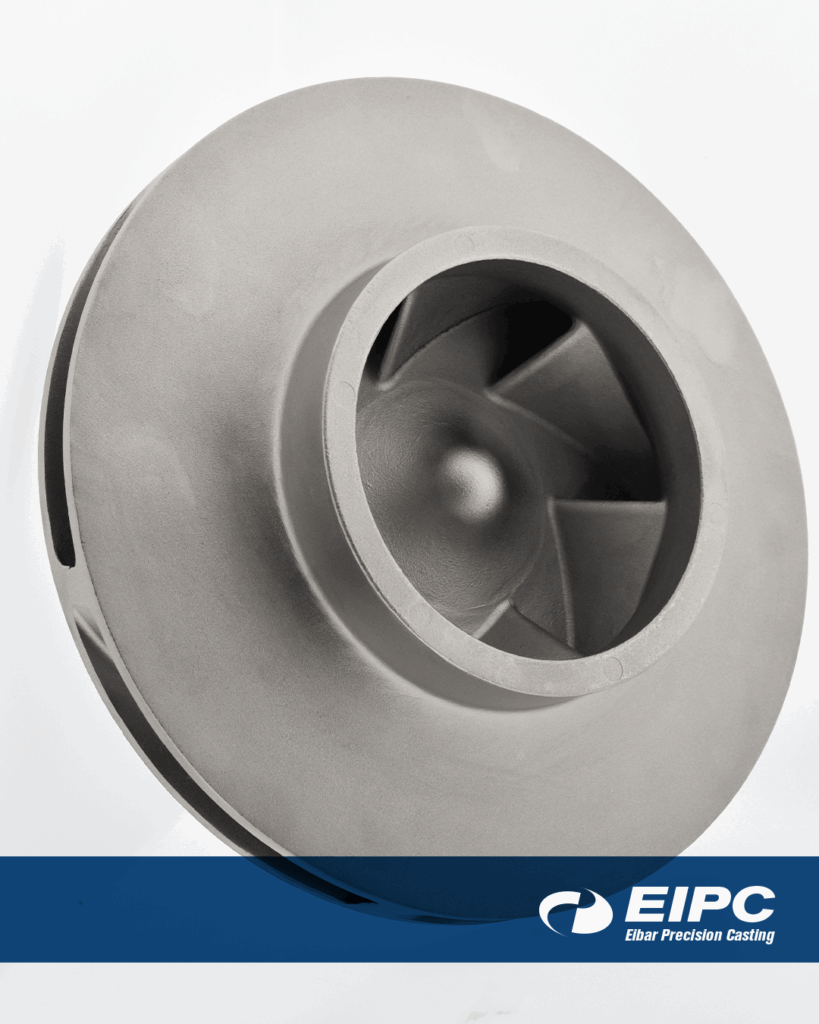

At the heart of many complex industrial systems—centrifugal pumps, compressors, turbines, and mixers—lies a key component: the impeller. Its role is as critical as its design: transferring energy from the motor to the fluid, generating pressure and flow. Investment casting (lost-wax casting) has become the preferred technology for manufacturing these components: when high performance, operational reliability, and dimensional precision are required, investment casting becomes a strategic choice.

In this article, we explore how investment casting is revolutionizing the production of impellers, its advantages, industrial applications, and the added value it brings to multiple industries.

What is an impeller and why is it so important?

An impeller is the rotating component of equipment such as centrifugal pumps, compressors, turbines, and agitators. Its function is to transmit energy from the motor to the fluid, generating pressure and movement. Impellers often have complex shapes, with curved blades, internal channels, and precise surfaces that determine hydraulic performance, energy efficiency, and machinery durability.

The quality and design of the impeller directly affect pumping capacity, generated pressure, noise levels, wear, and the overall lifespan of the system. For this reason, manufacturing high-precision, durable, and reliable impellers is a key technical challenge in industrial engineering.

There are multiple types of impellers depending on the application:

- Open: without cover, ideal for liquids with suspended solids.

- Semi-open: with a partial cover, balancing efficiency and solids-handling capacity.

- Closed: with double cover, offering the highest hydraulic efficiency.

- Multistage: used in high-pressure pumps.

In all cases, dimensional accuracy, dynamic balance, and surface quality are decisive for performance. This is where investment casting plays a vital role.

Key advantages of investment casting for impellers

The choice of investment casting for impeller production is driven by a combination of technical and economic advantages that set it apart from conventional methods such as machining or sand casting:

- – Superior dimensional accuracy: Enables tight tolerances, typically within the CT4 to CT7 range, with consistent repeatability across parts. Each impeller matches the original design parameters—critical for hydraulic performance and interchangeability in series.

- – Excellent surface finish: Achieves roughness levels between 0.8 and 6.3 μm, drastically reducing friction and turbulence in fluid flow, maximizing energy efficiency and equipment lifespan.

- – Complex geometries and design freedom: Allows the production of impellers with curved blades, thin walls, internal channels, and intricate details virtually impossible to achieve with other methods. This enables hydraulic optimization and adaptation to specific applications without geometry restrictions.

- – Wide material variety: From stainless steel and aluminum alloys to special bronzes, titanium, and even high-temperature alloys (such as Inconel), investment casting adapts to any requirement in terms of strength, hardness, weight, or conductivity.

- – Reduced post-machining: Impellers come out nearly finished; fewer secondary processes minimize material waste, lead times, and costs without compromising accuracy.

- – Scalable production: Suitable for both small series and prototypes as well as large-scale production requiring strict quality control and consistency.

Materials and technical considerations

The material versatility of investment casting is a key factor in manufacturing high-performance impellers. Commonly used materials include:

– Stainless steels (AISI 304, 316, etc.): Corrosion resistance, high toughness, and durability. Ideal for harsh environments, high temperatures, or chemical contact.

– Bronze and special copper alloys: Used where wear resistance, good hydraulic properties, and conductivity are required.

– Aluminum alloys: Valued for low weight and excellent machinability, especially in equipment where lightness is a priority.

– Titanium alloys and superalloys (Inconel, Monel, etc.): Essential in equipment exposed to extreme temperatures, high pressures, or highly corrosive environments, such as turbines, aerospace, and chemical plants.

Due to the dimensional tolerances of the process, homogeneous densities and controlled weights can be achieved, ranging from just a few grams to several kilograms, adapting to the needs of each industrial system.

Types and designs of investment-cast impellers

Investment casting enables the production of both standard closed impellers and open, semi-open, channel, or custom designs tailored to the required hydraulic profile. Both standardized models and co-engineered designs (developed collaboratively between customer and foundry) can be reproduced with precision to optimize efficiency for specific applications.

In practice, two main structural categories of impellers are produced with this method:

– Semi-open front type: Consists of a back cover plate and blades. While typically less hydraulically efficient, performance can improve if an adjustable seal ring is included.

– Semi-open rear type: Integrates a front cover plate and blades, suitable for applications requiring solids passage or other specific flow conditions.

Both types can be manufactured in different materials and sizes, depending on industry and application requirements.

Industrial applications where quality is decisive

Investment-cast impellers have their greatest advantage in applications where hydraulic efficiency, structural strength, dimensional accuracy, and durability are essential for operational success:

- Energy and power generation: Pumps and turbines in thermal, nuclear, and hydroelectric plants.

- Aerospace: Compressors, hydraulic systems with critical precision requirements, and components subject to high demands of weight, strength, and temperature.

- Chemical and petrochemical industry: Process equipment, reactors, and fluid pumping systems handling corrosive or abrasive substances.

- Food and pharmaceutical industry: Polished stainless-steel impellers meeting hygienic requirements.

- Naval and maritime sector: Pumps and propulsion systems resistant to saltwater and cavitation.

- Automotive and agricultural machinery: Hydraulic, cooling, and circulation systems requiring long-term reliability.

- Water treatment: Centrifugal pump impellers handling solids and abrasives.

- Medical engineering: Surgical pumps and microcomponents where precision and biocompatibility are indispensable.

Customization, innovation, and quality assurance

The true strength of investment casting in impellers lies in the ability to fully customize each component to the customer’s unique needs. From selecting the most suitable alloy for the operating environment to engineering blade designs for specific flow conditions, adaptability is total, and each batch can be unique.

Comprehensive quality controls—dimensional, metallographic, dynamic balance, and functional—ensure reliability and repeatability for every impeller before delivery to the end user.

Comprehensive quality controls—dimensional, metallographic, dynamic balance, and functional—ensure reliability and repeatability for every impeller before delivery to the end user.

Conclusion

The investment-cast impeller represents the optimal solution for industries demanding maximum efficiency, precision, and innovation. Thanks to this process, it is possible to meet the most demanding expectations across sectors, contributing to the reliability, competitiveness, and sustainability of critical machinery in modern industrial processes.

Investing in investment-cast impellers means investing in quality, efficiency, and the future. EIPC has the expertise, technology, and service-oriented approach necessary to develop the perfect impeller for every industrial challenge