EIPC acquires new FARO three-dimensional scanning system for part quality control

In a company like EIPC, specialised in precision foundry of high mechanical performance metal parts for various sectors, quality control is a constant that is carried out at all stages of the manufacturing process to ensure that the most demanding standards are met.

One of the most rigorous control processes at EIPC is part inspection. After casting, each part is subjected to a detailed inspection to detect any defects or imperfections.

Tests performed in the inspection process are critical to ensure the quality and integrity of the parts, and range from the most basic, such as visual inspection, to the most complex, such as non-destructive testing (e.g. ultrasonic, radiographic or liquid penetrant inspection, to detect cracks, inclusions or internal porosities) or dimensional control, the test that requires the highest degree of precision.

We carry out precise measurements of the dimensions of the part to verify that it complies with the tolerances specified in the technical drawing, using measuring tools such as calipers, micrometers, CMMs (coordinate measuring machines). When a part or tool is so complex that contact probes cannot be used to capture all its measurements, it is necessary to have a suitable system, such as 3D laser scanning systems to obtain accurate measurements of the geometric characteristics of the part.

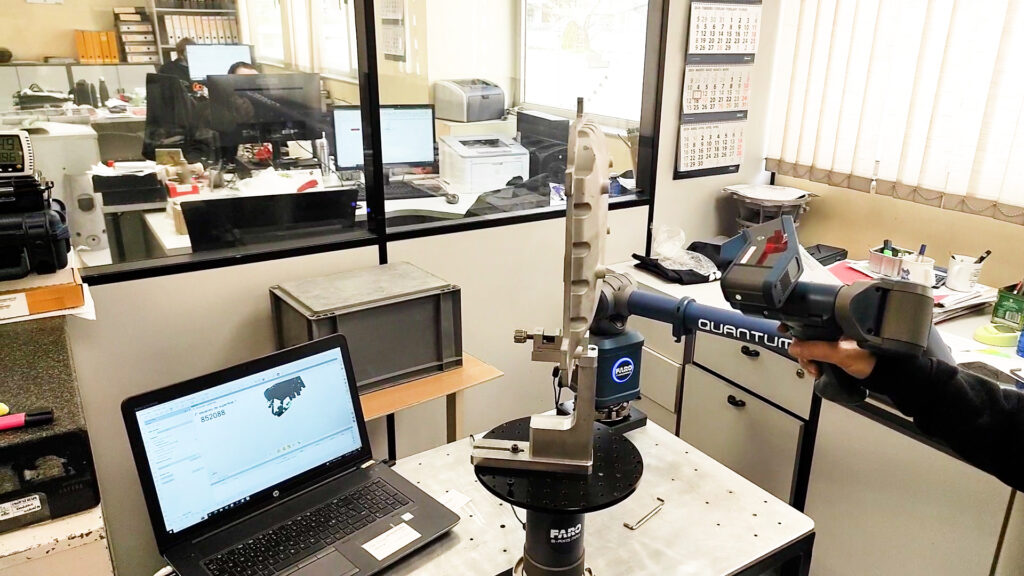

One of our latest additions to EIPC’s arsenal of measurement tools is the FARO Quantum ScanArms 3D non-contact measurement system, which combines the measurement capabilities of a portable coordinate measuring machine (CMM) with the non-contact functionality of a laser line probe.

The acquisition of this equipment by EIPC has been supported by the Basque Government through the RENOVE INDUSTRIA 4.0 programme.

RENOVE INDUSTRY 4.0 programme aims to promote investments in new machinery and advanced equipment, both hardware and software, with the aim of modernising industrial environments so that they can face or tackle Industry 4.0 projects within the field of Advanced Manufacturing.

EIPC standards are the highest when it comes to assessing the quality of our processes and products.